Creating a Materials Innovation Infrastructure

Category

Published on

Abstract

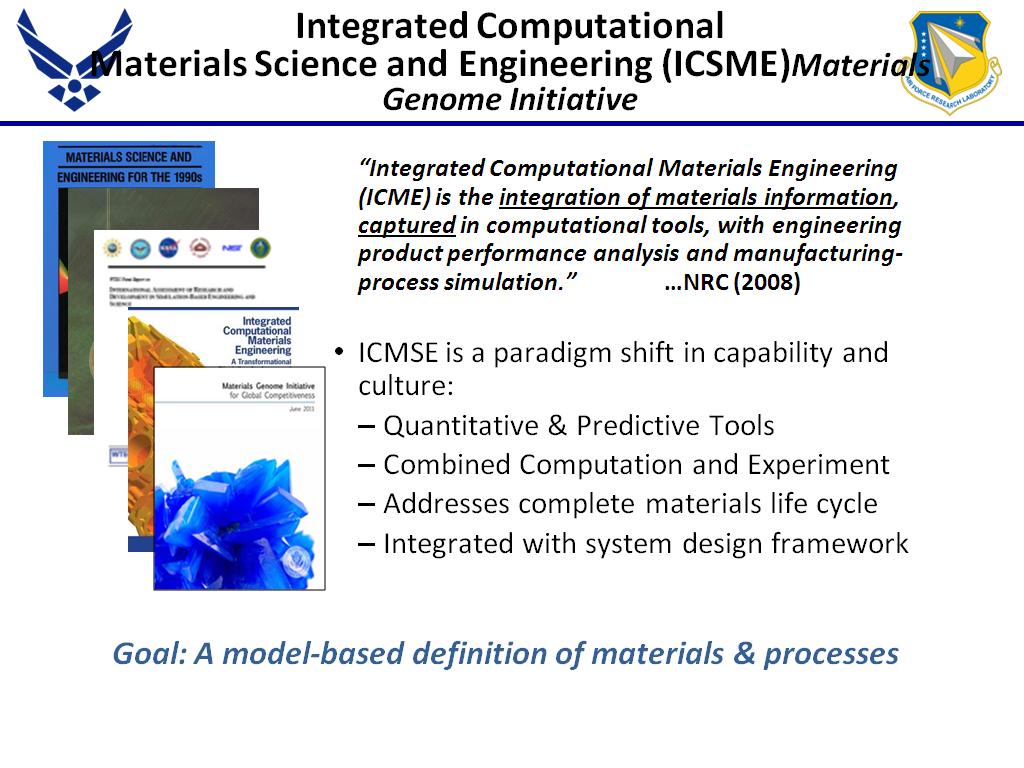

Establishing a pervasive Integrated Computational Materials Engineering (ICME) environment requires model-based definition of materials and processes in a historically ad hoc and disconnected research environment, which in turn demands a significant paradigm shift in both capability and culture. Commercial software and other tools developed in isolation from their actual users and use context have had a poor track record of supporting the complex computation and data flows that are essential to the practice of ICME. In fact, the increasing obsolescent and artificial separation of scientist from software developer actively impedes progress in creating communities of practice that share the burden of software and infrastructure development in order to reach pragmatic science and engineering driven goals.

A presentation will be delivered on efforts to establish such a community of practice within a large materials research laboratory in order to develop an Integrated Collaborative Environment (ICE) that aids in materials and process discovery. The central challenge to implementing an integrated and federated system is in balancing the conflicting needs of insuring long term viability by utilizing software design best practices such as separation of concerns and component driven architectures, with immediacy of user needs for simple, flexible, autonomous and secure information management. Additionally, system behaviors modeled after an optimized research process must not impede the ability of practitioners to perform mission critical research. Key elements and design choices of the emerging ICE system will be presented in the context of a requirements-driven use case that represents the larger needs for tool staging, workflow integration, material provenance, and laboratory management.

Bio

Mr. Matthew Jacobsen is the project manager and technical lead for the development and acquisition of enterprise scientific toolsets for the Materials and Manufacturing Directorate (RX) of the Air Force Research Laboratory. Prior to leading RX-wide efforts such as the Integrated Collaborative Environment (ICE), he served as a systems developer and analyst for a variety of software platforms, including financial and portfolio management, scientific process management, and data analysis. Mr. Jacobsen holds a BS in Management Information Systems, and an MS in Logistics and Supply Chain Management, both from Wright State University in Dayton, Ohio.

Dr. Charles Ward leads efforts in Integrated Computational Materials Science and Engineering at the Air Force Research Laboratory’s Materials and Manufacturing Directorate. He is an Adjunct Faculty member of Materials Engineering at the University of Dayton and is also Editor of TMS’s Integrating Materials and Manufacturing Innovation journal. His professional career has spanned 28 years, serving in several roles in research, engineering, and management. His research has focused on the microstructure-property relationships in titanium and titanium aluminide alloys. He has served as manager for the Air Force's basic research program in metals and then as an engineer on the F-35 propulsion program. He also served as staff officer to the Assistant Secretary of the Air Force for Acquisition, and then Air Force liaison for materials research and development in Europe. Previous to his current position, he served as Chief of the Metals, Ceramics and Nondestructive Evaluation Division of the Materials and Manufacturing Directorate. Dr. Ward received his PhD in Materials Science and Engineering from Carnegie Mellon University and is a Fellow of ASM International and an active member of TMS.

Credits

Jacobsen, Ward

Materials and Manufacturing Directorate, Air Force Research Laboratory, Wright-Patterson AFB, OH 45433

Cite this work

Researchers should cite this work as follows:

Tags

-

1. Creating a Materials Innovatio…

0

00:00/00:00

1. Creating a Materials Innovatio…

0

00:00/00:00 -

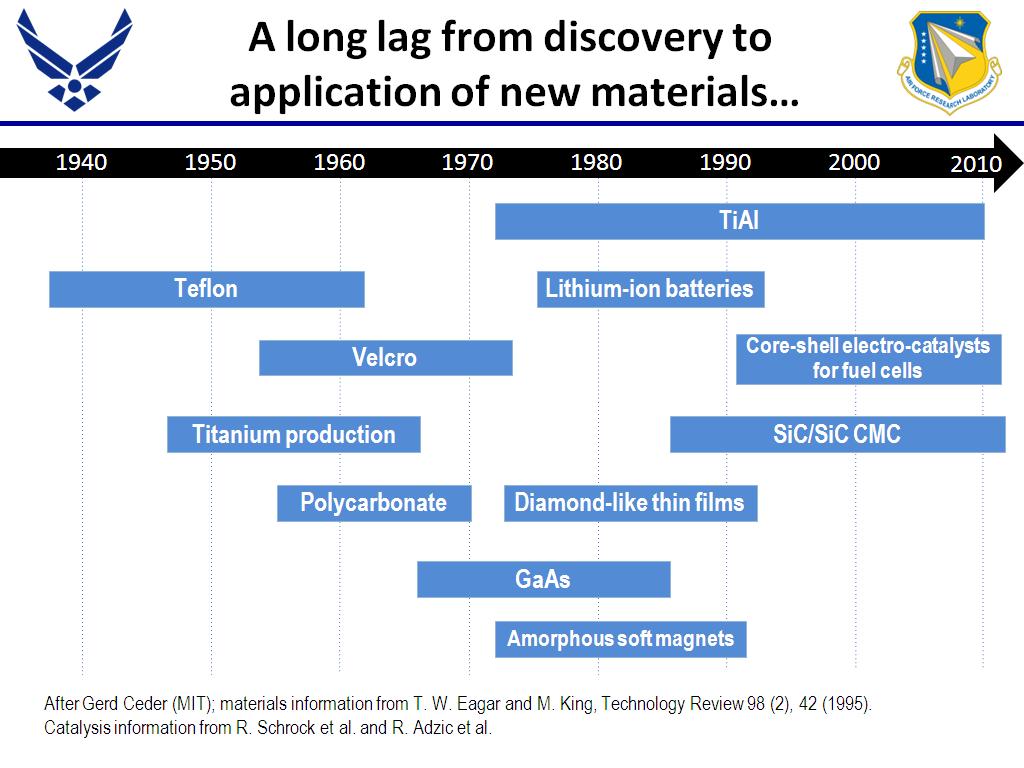

2. A long lag from discovery to a…

126.96029362696029

00:00/00:00

2. A long lag from discovery to a…

126.96029362696029

00:00/00:00 -

3. Integrated Computational Mater…

166.86686686686687

00:00/00:00

3. Integrated Computational Mater…

166.86686686686687

00:00/00:00 -

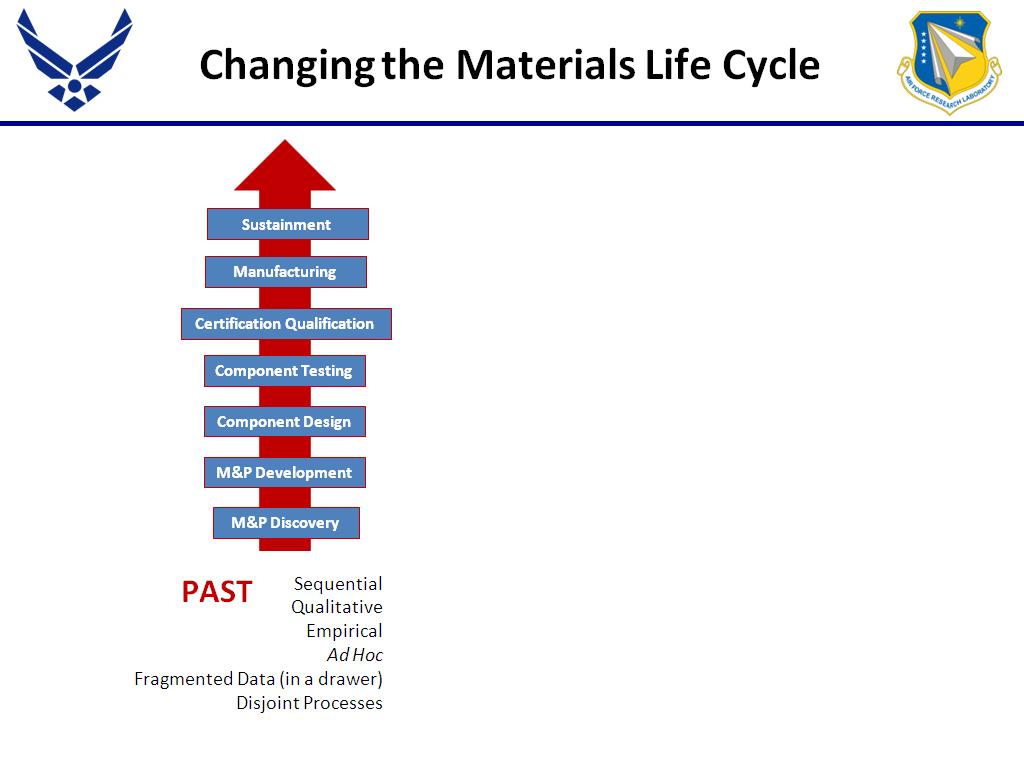

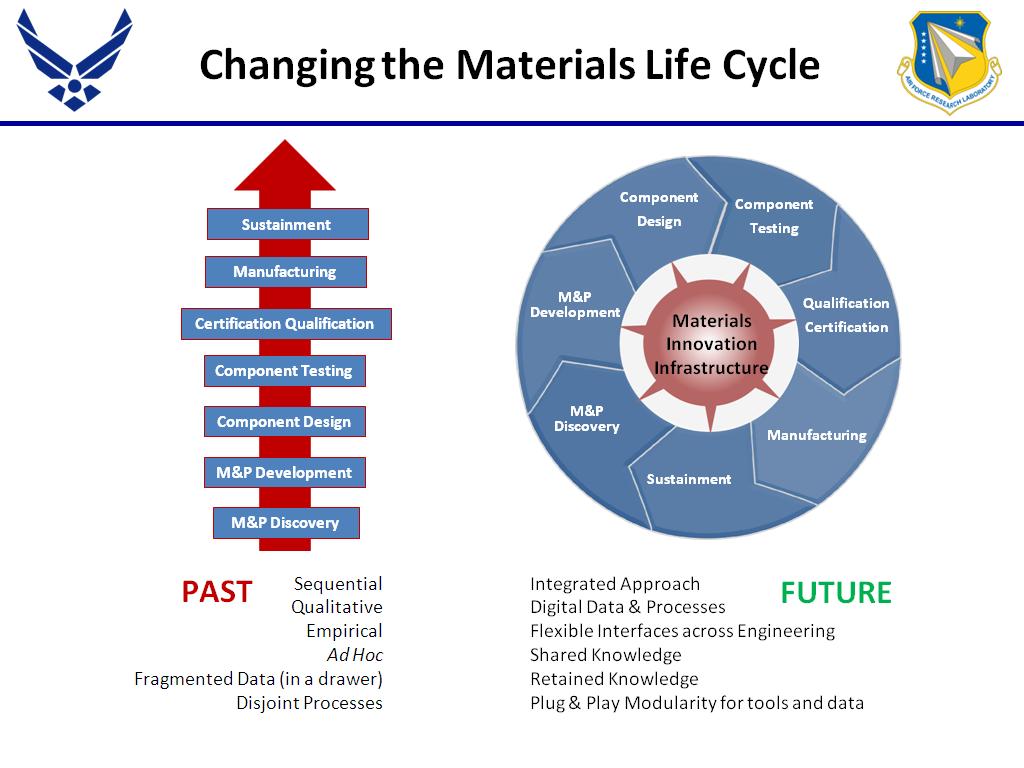

4. Changing the Materials Life Cy…

251.05105105105105

00:00/00:00

4. Changing the Materials Life Cy…

251.05105105105105

00:00/00:00 -

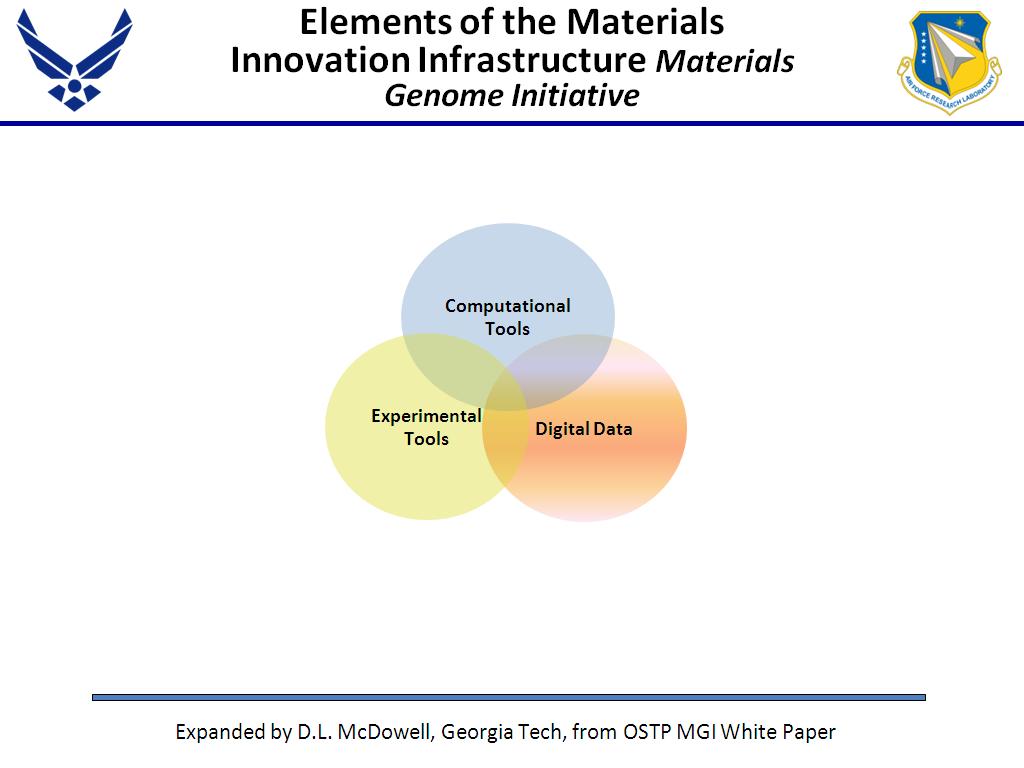

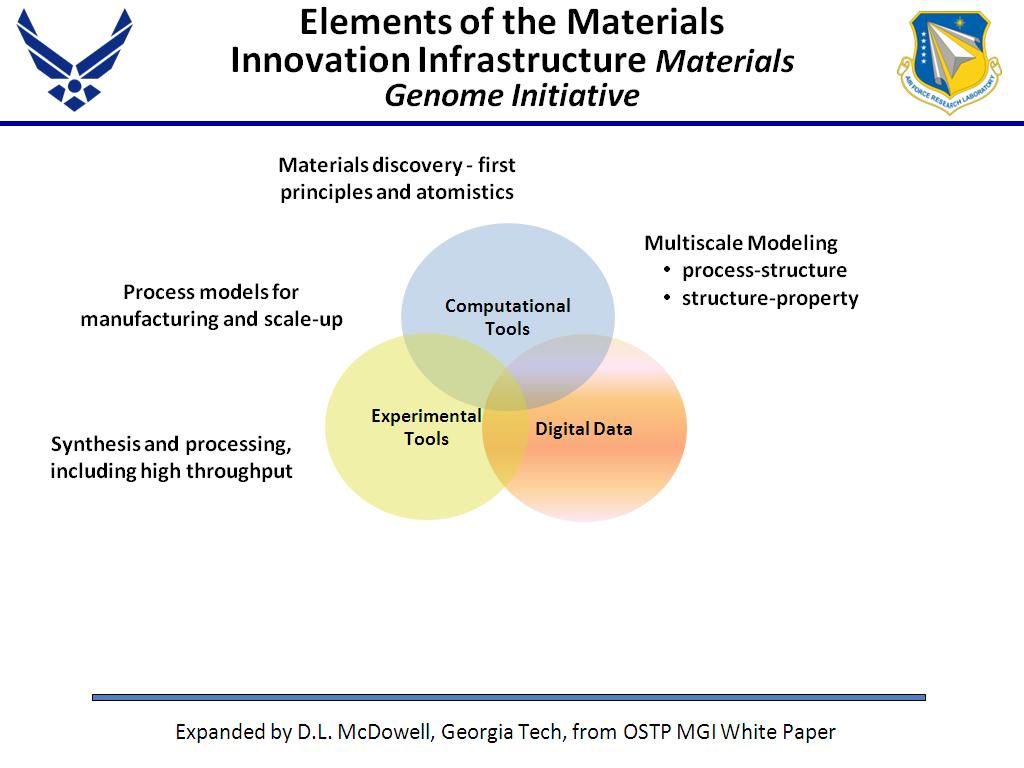

5. Elements of the Materials Inno…

289.85652318985655

00:00/00:00

5. Elements of the Materials Inno…

289.85652318985655

00:00/00:00 -

6. Air Force Research Laboratory …

365.06506506506508

00:00/00:00

6. Air Force Research Laboratory …

365.06506506506508

00:00/00:00 -

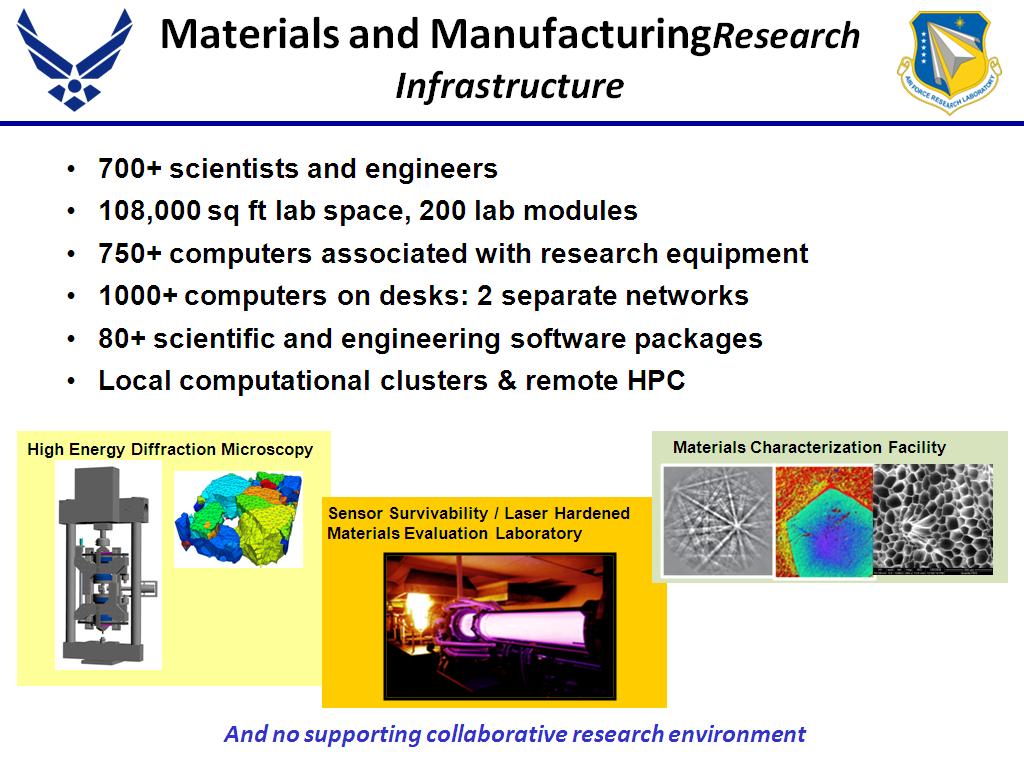

7. Materials and ManufacturingRes…

416.14948281614949

00:00/00:00

7. Materials and ManufacturingRes…

416.14948281614949

00:00/00:00 -

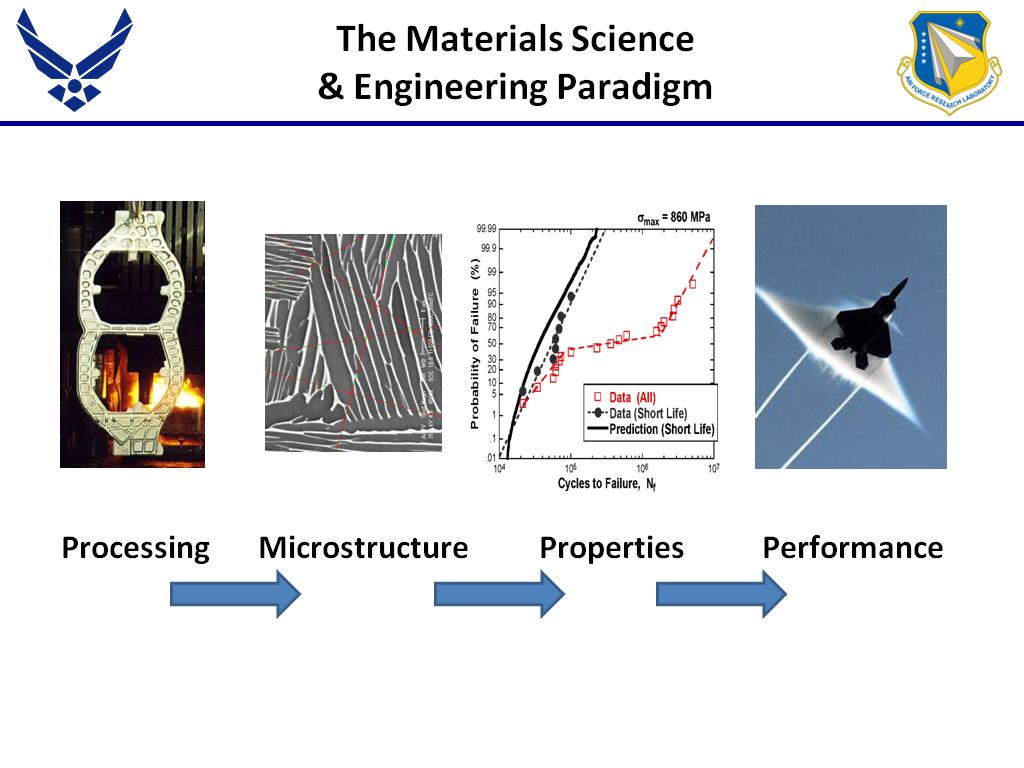

8. The Materials Science & Engine…

456.99032365699031

00:00/00:00

8. The Materials Science & Engine…

456.99032365699031

00:00/00:00 -

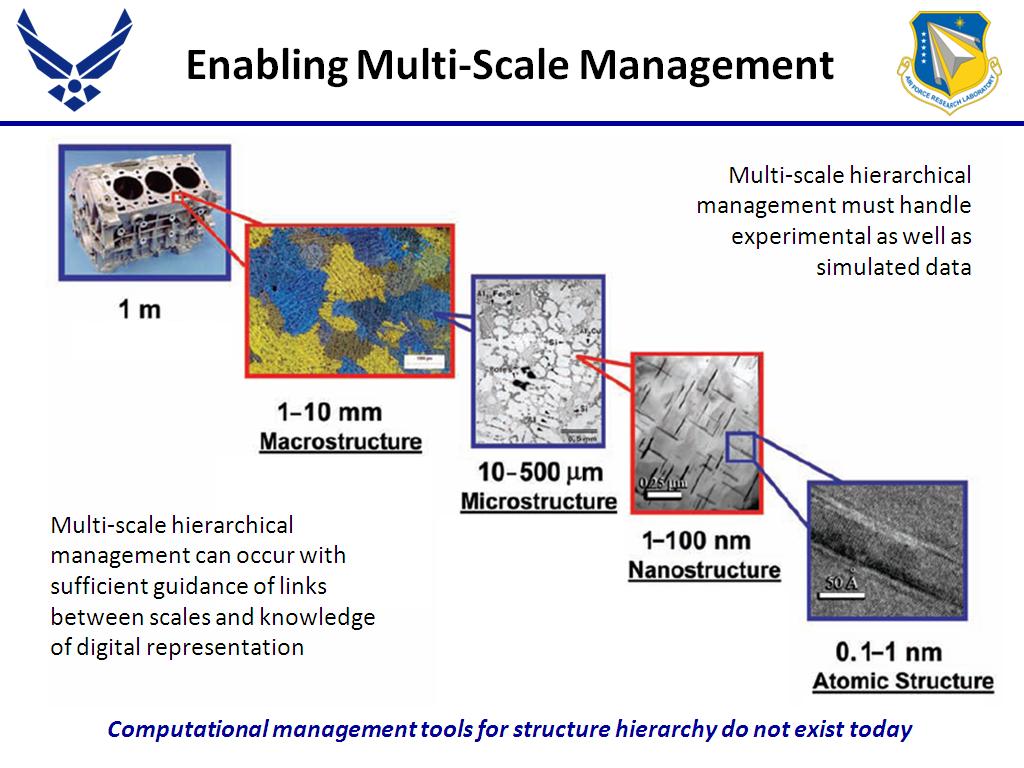

9. Enabling Multi-Scale Managemen…

484.75141808475144

00:00/00:00

9. Enabling Multi-Scale Managemen…

484.75141808475144

00:00/00:00 -

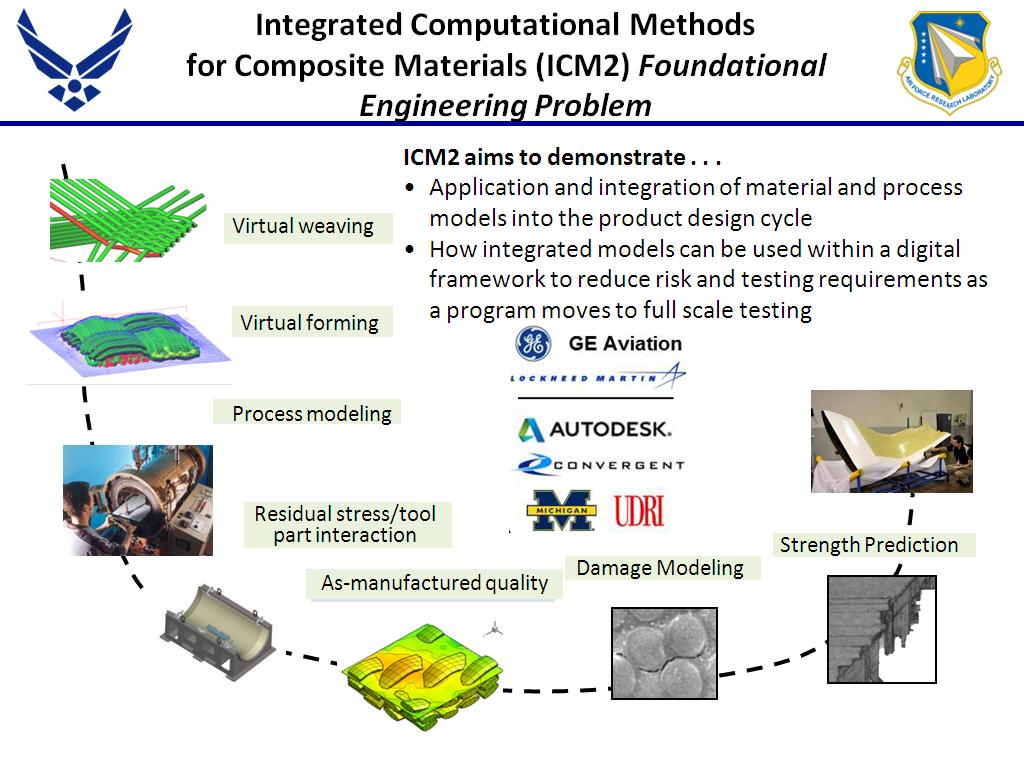

10. Integrated Computational Metho…

541.307974641308

00:00/00:00

10. Integrated Computational Metho…

541.307974641308

00:00/00:00 -

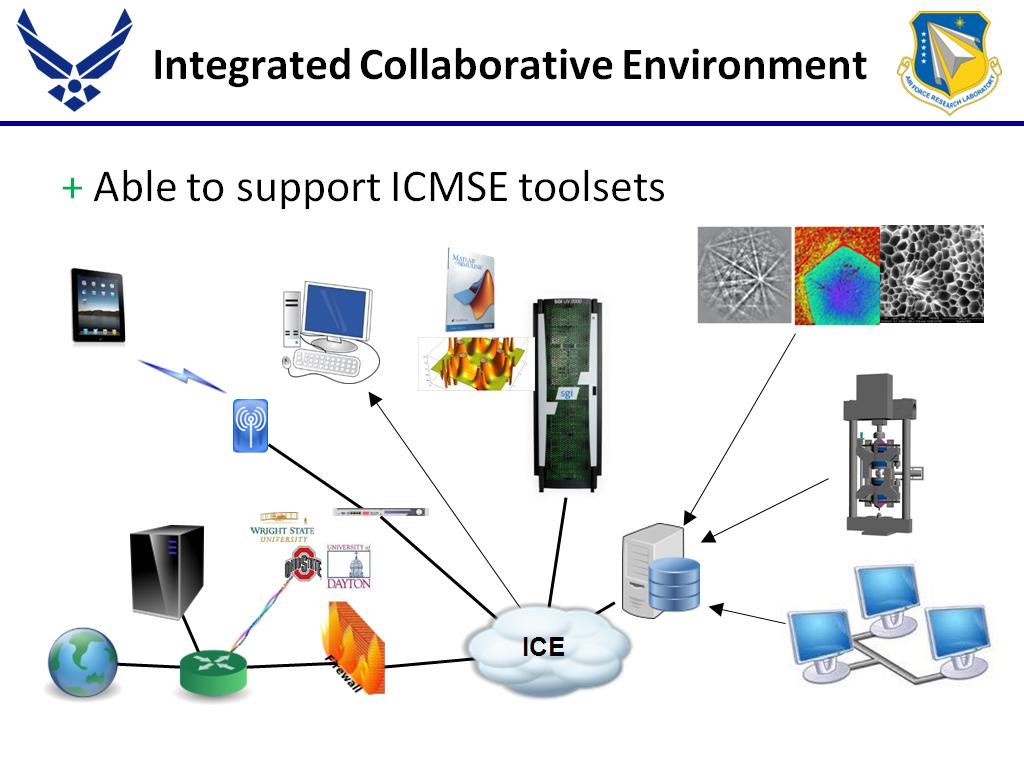

11. Integrated Collaborative Envir…

592.75942609275944

00:00/00:00

11. Integrated Collaborative Envir…

592.75942609275944

00:00/00:00 -

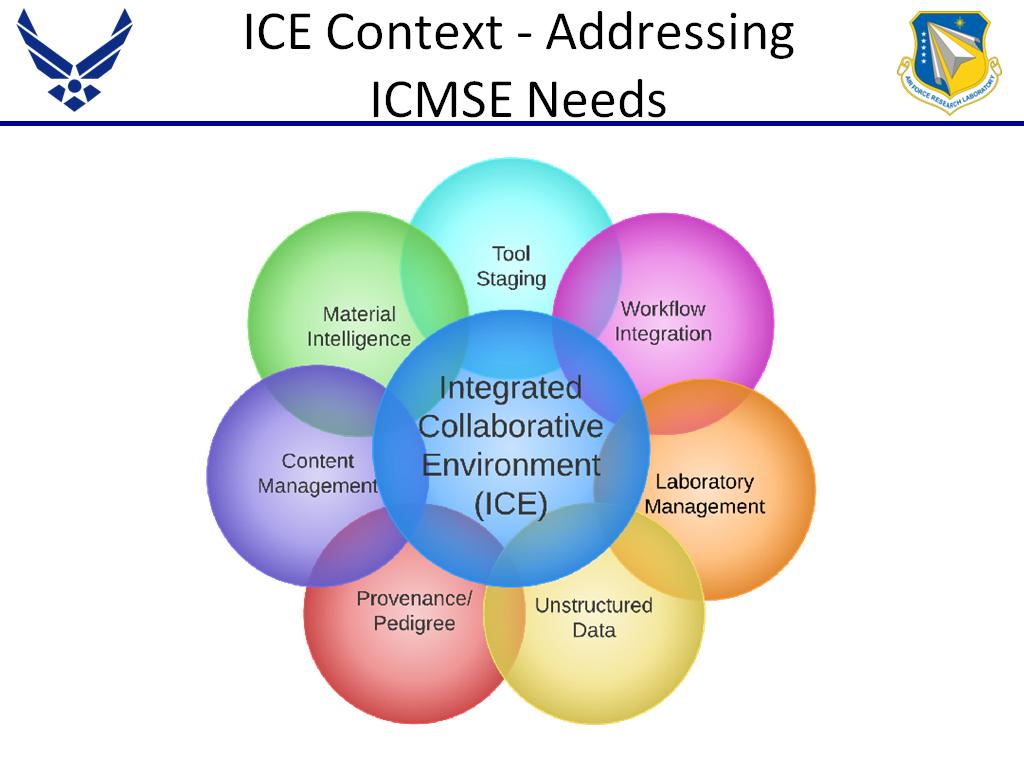

12. ICE Context - Addressing ICMSE…

714.08074741408075

00:00/00:00

12. ICE Context - Addressing ICMSE…

714.08074741408075

00:00/00:00 -

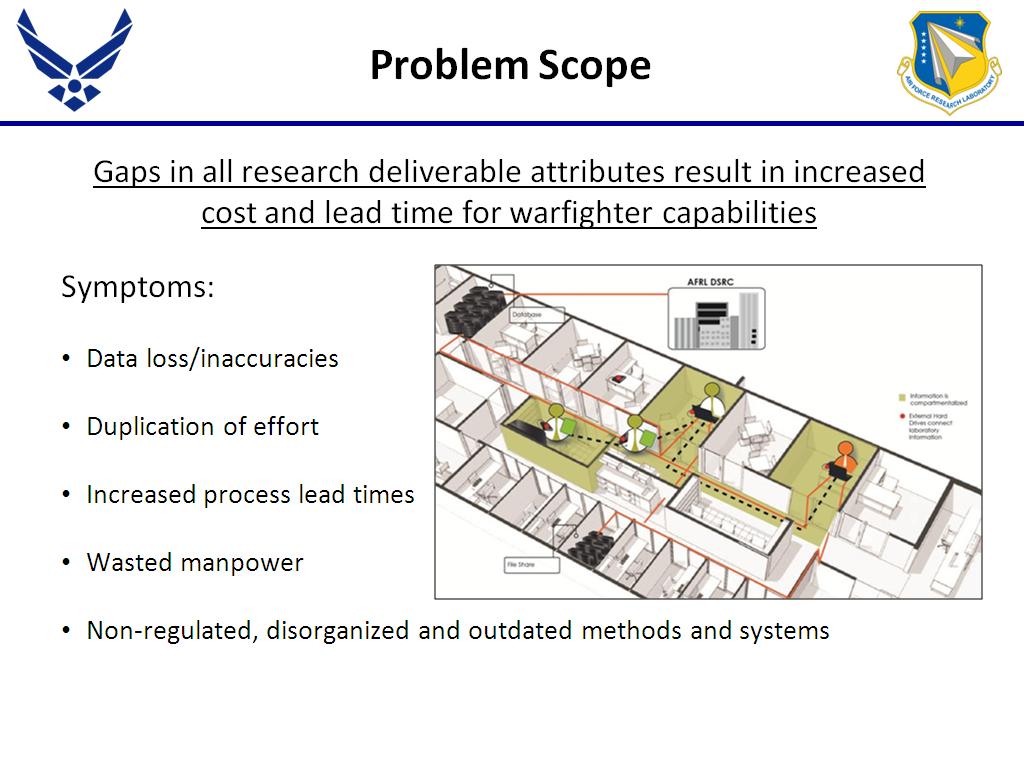

13. Problem Scope

903.03636970303637

00:00/00:00

13. Problem Scope

903.03636970303637

00:00/00:00 -

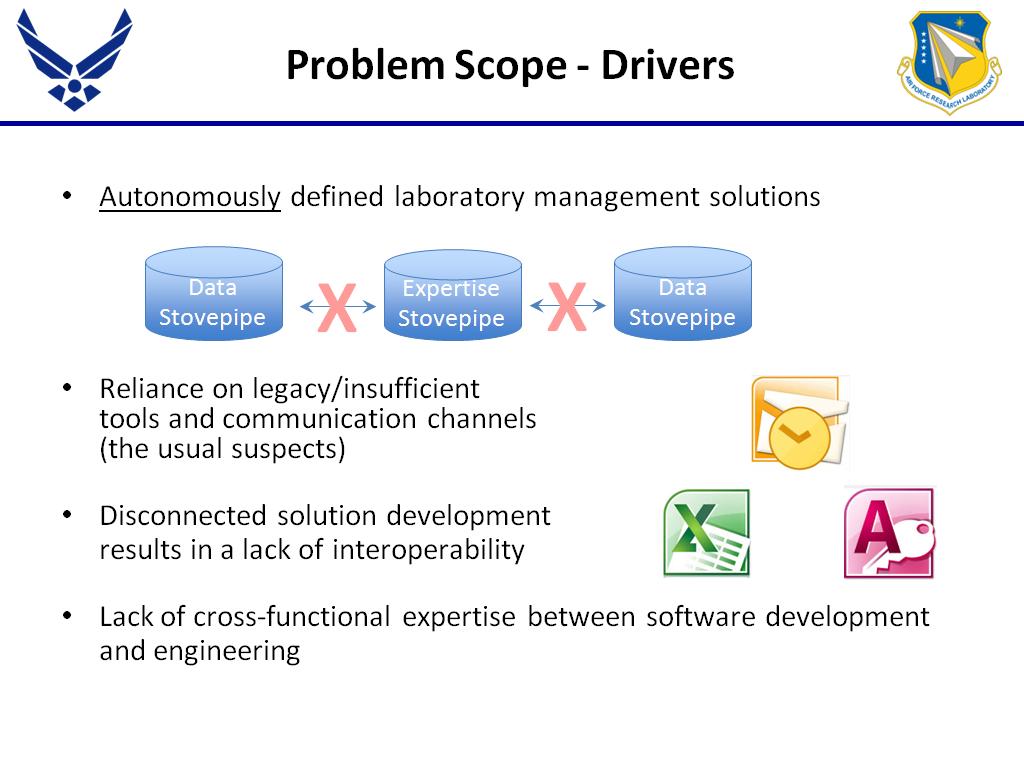

14. Problem Scope - Drivers

1017.1171171171171

00:00/00:00

14. Problem Scope - Drivers

1017.1171171171171

00:00/00:00 -

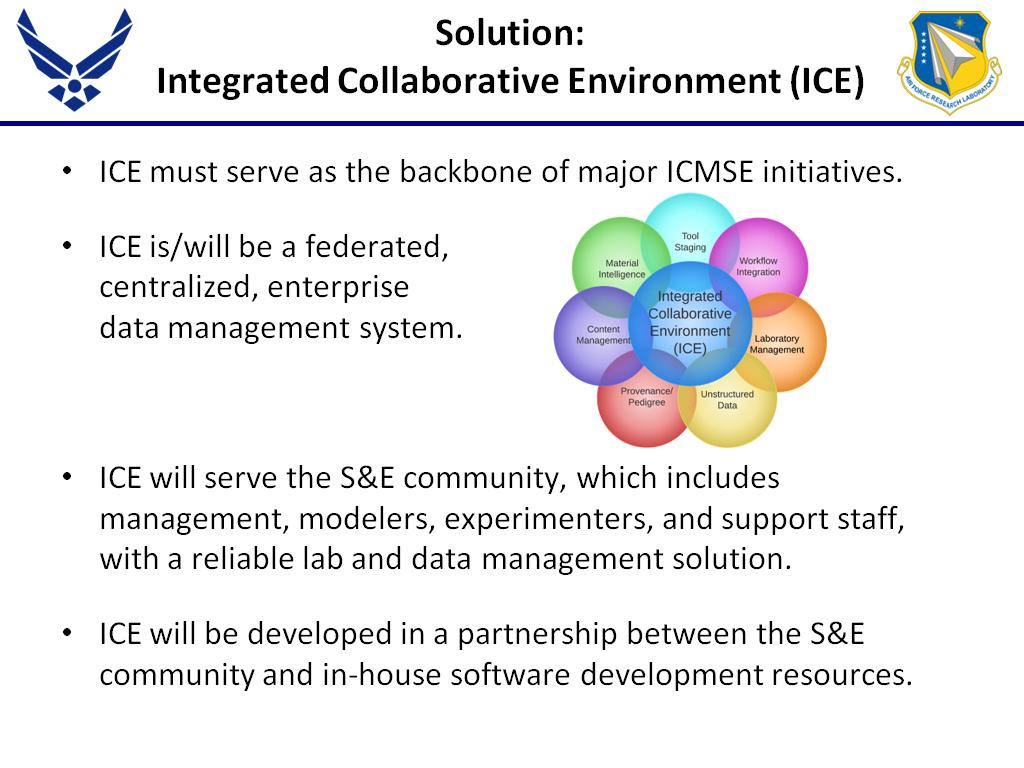

15. Solution: Integrated Collabora…

1082.5158491825159

00:00/00:00

15. Solution: Integrated Collabora…

1082.5158491825159

00:00/00:00 -

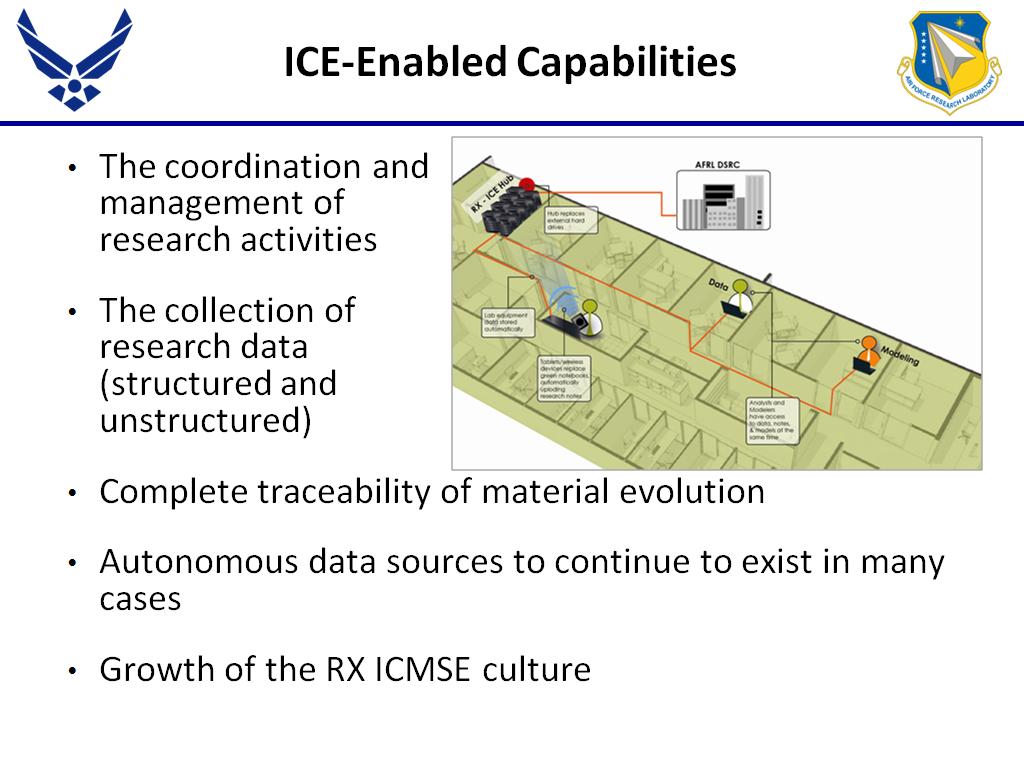

16. ICE-Enabled Capabilities

1182.6159492826159

00:00/00:00

16. ICE-Enabled Capabilities

1182.6159492826159

00:00/00:00 -

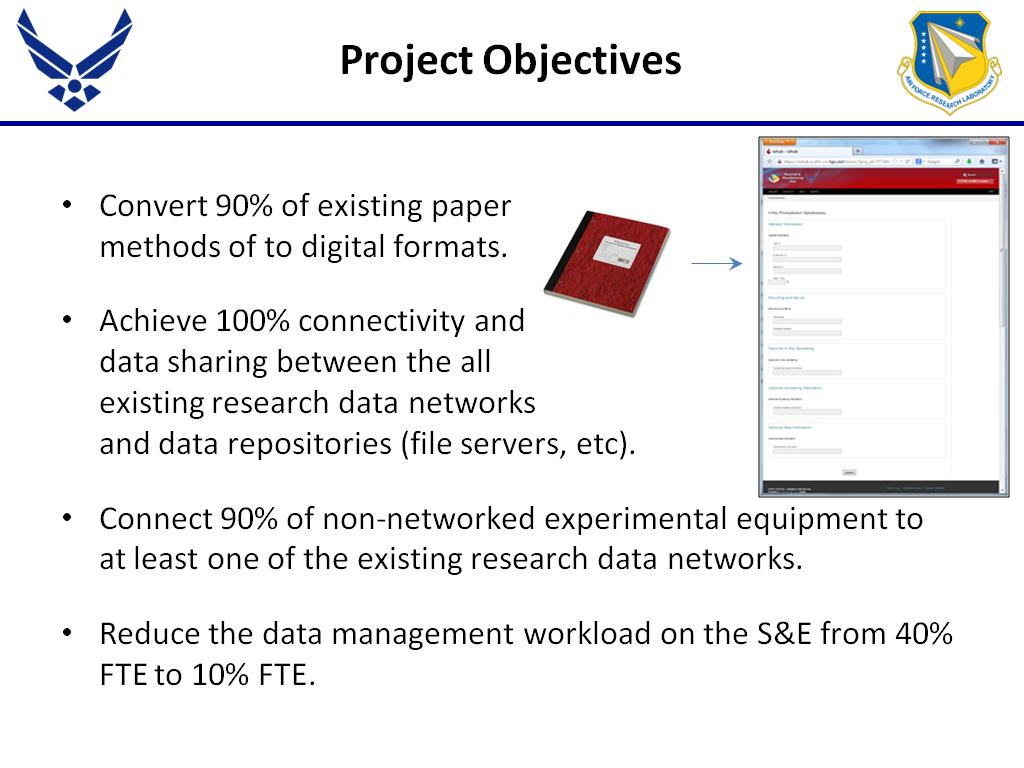

17. Project Objectives

1283.6503169836503

00:00/00:00

17. Project Objectives

1283.6503169836503

00:00/00:00 -

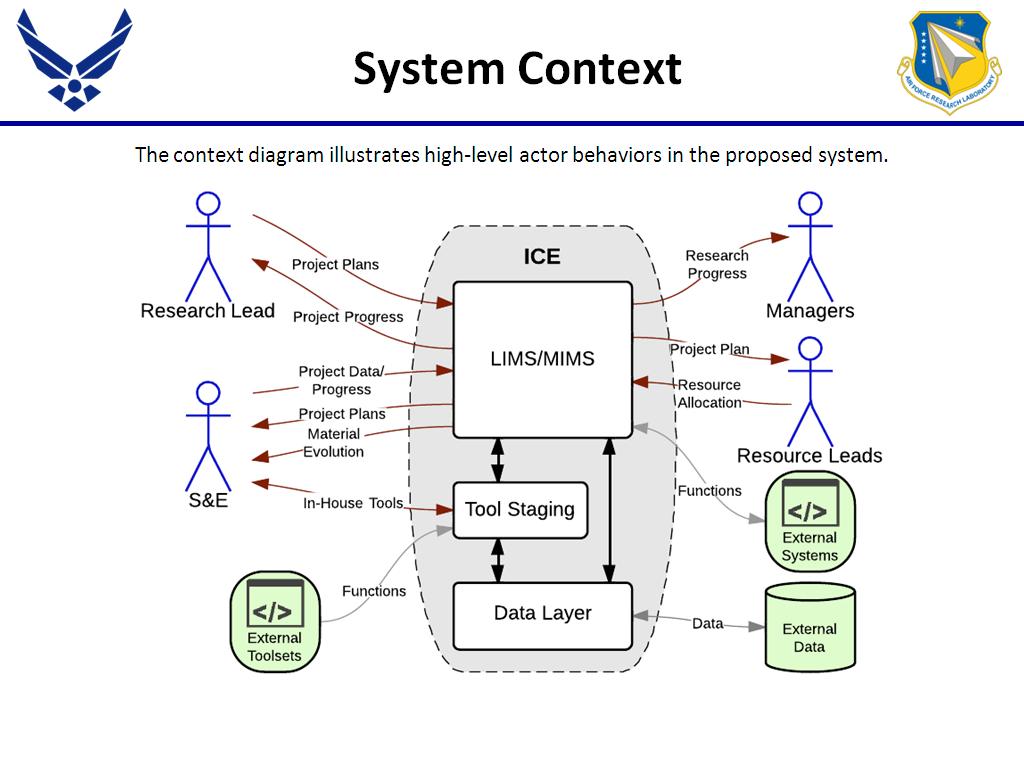

18. System Context

1394.9616282949617

00:00/00:00

18. System Context

1394.9616282949617

00:00/00:00 -

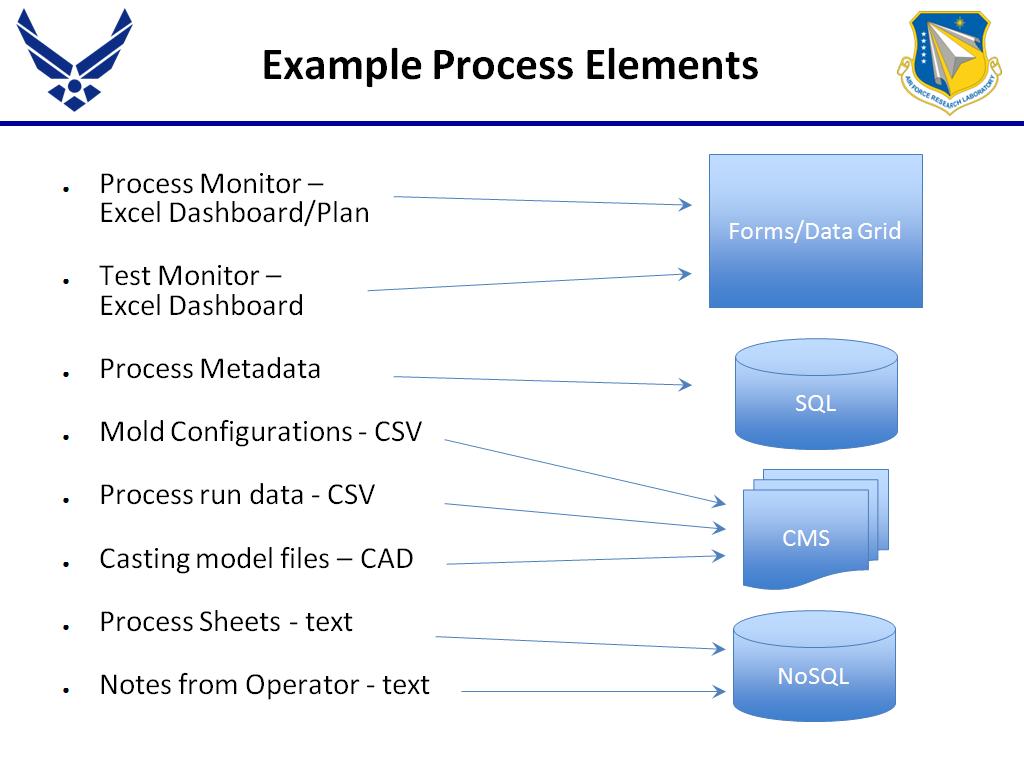

19. Example Process Elements

1468.4684684684685

00:00/00:00

19. Example Process Elements

1468.4684684684685

00:00/00:00 -

20. Challenges

1610.8441775108443

00:00/00:00

20. Challenges

1610.8441775108443

00:00/00:00 -

21. The Hub in AFRLInitial Impress…

1678.2782782782783

00:00/00:00

21. The Hub in AFRLInitial Impress…

1678.2782782782783

00:00/00:00 -

22. The Hub in AFRLStrengths

1769.8031364698031

00:00/00:00

22. The Hub in AFRLStrengths

1769.8031364698031

00:00/00:00 -

23. The Hub in AFRLConsiderations

1846.5465465465466

00:00/00:00

23. The Hub in AFRLConsiderations

1846.5465465465466

00:00/00:00 -

24. OpportunitiesOutstanding needs

2037.4040707374043

00:00/00:00

24. OpportunitiesOutstanding needs

2037.4040707374043

00:00/00:00 -

25. Summary

2081.6816816816818

00:00/00:00

25. Summary

2081.6816816816818

00:00/00:00